RENEW

We were prompted to create a handheld tool that could be manufactured quickly and cheaply (at home even). After a conversation with a bike mechanic about the durability of hammers I was sold on the idea of a hammer that could be modularly repaired and adapted to fit the user’s needs.

Tools used:

Fusion360

Keyshot 8

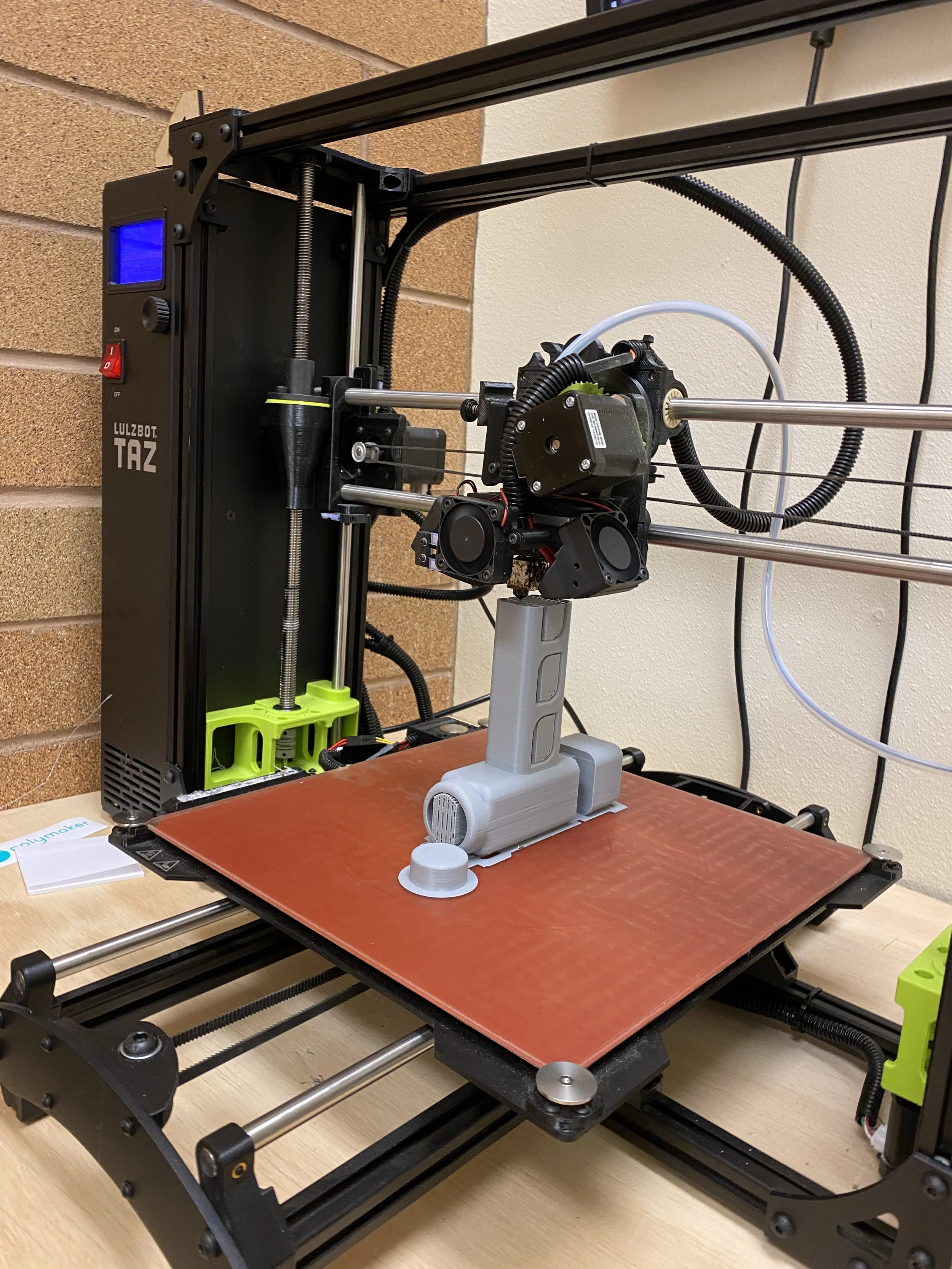

Cura 3D printer

FoamCore

Making a new hammer is sort of like re-inventing the wheel, but with this in mind I focused on the user being someone moving around and not having access to a full tool collection. With this situation in mind necessary action had to be made to limit size and weight while maintain structure, strength, and versatility.

Once the shape and mechanics were decided and tested, CAD files were made for all of the parts, and renders were processed to display the hammer in it’s context before actual modelling began.

Creating the physical hammer came with it’s own set of challenges, bad print scales, tolerances not holding up, ect. In the end however, after only a few tweaks, the hammer was able to be printed and assembled directly off the line.

In conclusion

This modular hammer concept was super fun to dream up and bring to life, and, in the future could be used to combat ‘consumable’ hammers with the ability to replace as you go and modify for different intended situations.